In today’s fast-paced technological world there are a few “smart” items that we rely on every day. You’ll be hard-pressed to find someone who doesn’t have a smartphone within arm’s reach at all times. And smart homes with central units to control heating and cooling, lights, security and more are becoming increasingly common.

If we apply the definition of smart to a warehouse one could say that a smart warehouse is a warehouse designed to operate with maximum efficiency by incorporating best practices, automation and other technologies to ensure that it can function at the highest level.

Third Party Logistics Smart Warehouse Approach

Smart warehouses approach their operations as a series of interconnected operations, processes and resources, each deserving attention and critical examination to promote efficiency, with the goal of lowering time and cost to perform. They also understand that the hand-off between each process provides both opportunities and challenges.

If you want to ensure your warehouse is a smart warehouse there are a variety of areas you can focus on to keep it running like a fine-tuned (smart) machine. These areas are:

- Automation

- Flexibility

- Real-Time Connection

Automate

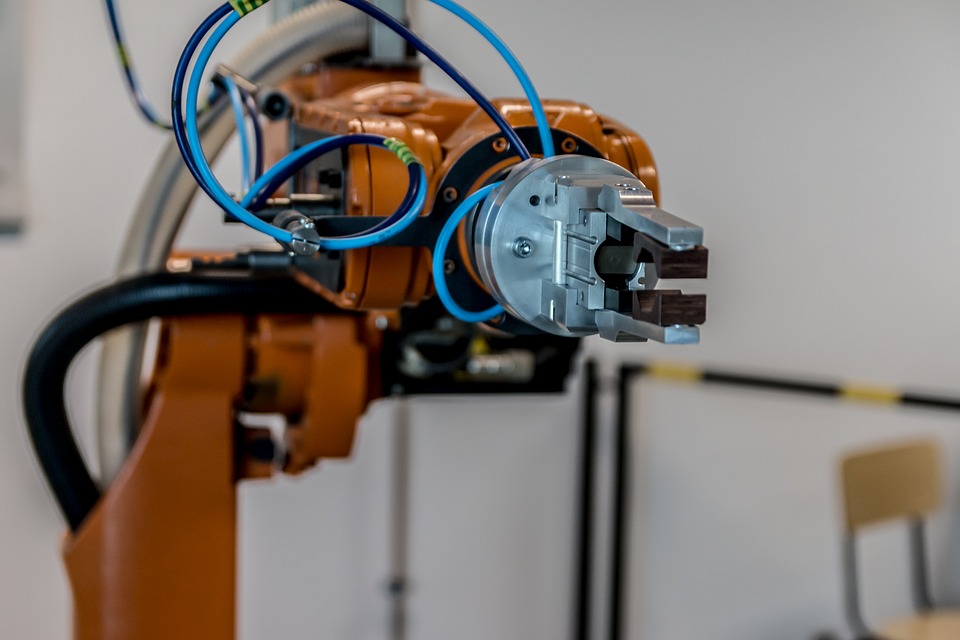

Perhaps the single most important factor is process automation. Smart Warehouses work to eliminate the use of manual labor and input wherever possible. In addition to helping reduce costs and manpower needs, process automation can increase shipping accuracy and the speed in which data is input, no matter what level of volume is being processed.

New Businesses

No two businesses will have the same use for or ability to automate at the same rate. For companies that are just beginning to tackle smart warehousing simple automation like software that provides alerts for every step along the order process or automatic billing software that ties together warehouse activity with accounting can immediately improve the efficiency of product production, packing and or shipping.

Invested Businesses

For businesses ready for a larger scale investment in automation, such as the recent large hardware purchase by rykerhardware.com, it’s important to understand both the short and long-term gains from the automation to ensure that they’re ready to take on the up-front cost. And while it’s not a hard and fast rule when implementing large-scale automation you should look to see labor savings outpacing automation costs by 2 to 1 two years after applying the new automation to the warehouse.

Flexibility

The second attribute of a Smart Warehouse is to stay nimble – or at least as nimble as possible. As noted above, the higher level of consistent throughput and processes may dictate a larger investment in “fixed” automation, so there may be a tradeoff to some degree, and some loss of nimbleness as the investment in fixed automation goes up.

A Smart Warehouse has two essential tasks with regard to the physical warehouse – the first is to optimize the warehouse as it exists, and the second is to manage and plan for future growth. In optimizing the space, reconfigurable racking and pick shelves are often used so they can be changed out quickly in response to new products or needs.

Real-Time Connection

A Smart Warehouse is expected to be fully integrated, fully transparent – and fully capable of providing their customers and stakeholders information about their inventory – as soon as it is handled. Visibility and Real Time are the basic standards of any Smart Warehouse. And, for the 3PL operator, if your 3PL Warehouse cannot demonstrate that capability, you can be sure that your competitors can and will.

For the Smart Warehouse, this means that information is updated as soon as tasks are completed – as opposed to waiting to process overnight. This allows the warehouse customer full visibility into the system so they can see the status of their inventory as it exists at the moment, as opposed to last night, or even two hours earlier.

Christopher Morgan Fulfillment

Christopher Morgan Fulfillment has access to more than 600,000 square feet of professionally managed, secure, dry storage space, warehousing & distribution in Milwaukee and in all regions of the United States.

Our facilities are located in:

- New Berlin, Wisconsin

- Milwaukee, Wisconsin

- Atlanta, Georgia

- Los Angeles, California

- East Brunswick, New Jersey

Direct To Customer

Direct To Customer

- Direct Response

- E-commerce Fulfilment

- Catalog/Print Advertising

- Continuity/Membership/Awards

- Customer Contact Center

Retail Distribution

Retail Distribution

- Big Box Retail Distribution

- Home Shopping

- Electronic Data Interchange (EDI)

- Experts at Retail Compliance

- Partner Testimonials

BUSINESS TO BUSINESS

- Warehousing & Distribution

- Lot Control

- Kitting/Light Assembly

- Inspection Services

- Repackaging & Rework Services